During one of the last projects I was working on, I found that the first programming jig I made had a serious draw back. It could only put the #1 pin of the programmer in two of the four corners. That meant that I could only program my board from one side. That was fine until I assembled the project in it's case. At that point, reprogramming was a difficult task that required disassembly, something I never considered when I designed the item and as it turned out it was almost impossible to do without destroying it. Annoying!

Three weeks ago I decided I wanted to flash some new firmware on my motorcycle remote so I could use it to put a GPS on my Kindle Fire. That meant I needed take it apart and risk destroying it. Not an exciting prospect. Then I thought, why don't I just build another programming jig like the last one only upside down. That seemed like a winner, because it was fast, but I didn't have any more 2x3 ISP headers. Bah! Since I needed to wait on a shipment from Digikey I went ahead drew up a custom circuit board and added a few bells and whistles and sent it to fabricator.

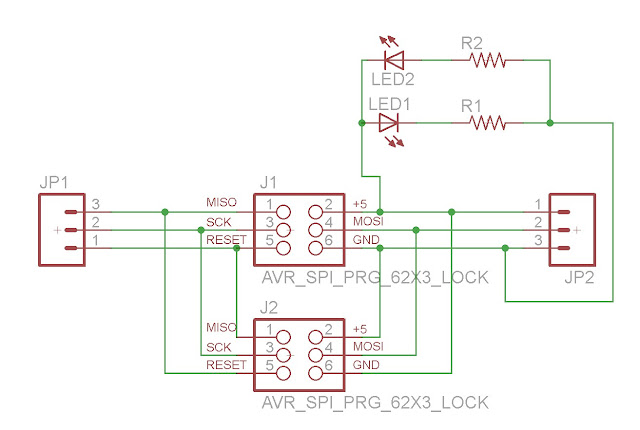

The bells and whistles I spoke of are a pair of ISP headers which are mirror images of each other and a pair of LEDs that point to the #1 pin. When you plug into one the of the two headers, one of the two LEDs lights up pointing to the #1 pin. This function makes it easy to identify how to orient the PCB to the jig.

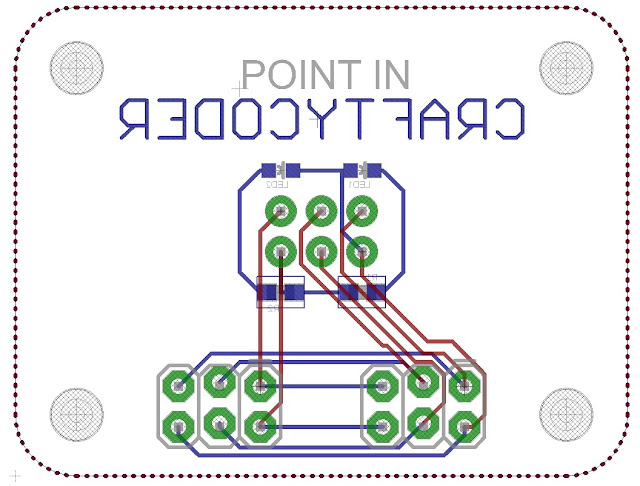

Below are images of the schematic and the board layout. The assembly is very easy. You just take two of the PCBs solder a pair of headers to the bottom board and pogo pegs to both and use some stand offs for strength. Check out the video for a better look at the final assembly.

You can modify the Eagle files posted below or send the pre-configured Gerber files directly to http://oshpark.com/ or your preferred fabricator to get some PCBs of your own.

Link to Eagle and Gerber Files |

|

| I drew up the board upside down for no particular reason. Blue is the outside and red is the inside. |

Comments

Post a Comment